Why Ceramic Coating is a Game-Changer for Automotive Enthusiasts

Why Ceramic Coating is a Game-Changer for Automotive Enthusiasts

Blog Article

Comprehending the Scientific Research Behind Ceramic Coating for Boosted Lorry Sturdiness

The science of ceramic covering is revolutionizing car upkeep by giving a formidable guard versus rough ecological variables. At its core, this modern technology uses the power of silicon dioxide and titanium dioxide to create a sturdy, safety layer. What specifically makes these substances so reliable in protecting a car's exterior? As we discover the detailed structure and application process of ceramic finishings, we uncover the secrets behind their premium defense and durability. Exactly how does this compare to traditional approaches, and what effects does it have for car maintenance in the lengthy term? The solutions might amaze you.

Structure of Ceramic Coatings

Ceramic coatings are mostly composed of silicon dioxide (SiO2), which is originated from all-natural materials like quartz and sand. This substance creates the backbone of the finish, offering its particular hardness and resistance to environmental aspects. In enhancement to SiO2, ceramic finishings often integrate titanium dioxide (TiO2) for boosted UV protection and enhanced resistance to toxic wastes. These nanocomposite materials develop a durable, chemical bond with the vehicle's surface, using a long-lasting protective layer.

The solution of ceramic coatings is a meticulous process where the concentration of SiO2 can considerably influence the covering's performance. Greater SiO2 web content generally results in greater resilience and firmness, adding to the coating's capability to withstand scratches and chemical etching. Nevertheless, the balance of components is important; way too much SiO2 can make the finishing brittle, while insufficient can compromise its safety residential or commercial properties.

Producers may additionally incorporate extra compounds, such as polysilazane, to improve adaptability and convenience of application. These additives enhance the coating's hydrophobic homes, guaranteeing water and pollutants grain off the surface area effortlessly. This engineered composition emphasizes the effectiveness of ceramic finishings in safeguarding a lorry's exterior against a selection of negative conditions.

Application Refine Explained

Using a ceramic layer to a car involves a number of crucial actions, each important to guaranteeing optimal bond and performance of the protective layer - ceramic coating. The procedure begins with an extensive laundry and purification of the car's surface area to remove dirt, crud, and previous waxes or sealants. This action is vital as any type of pollutants left on the surface can hinder the coating's capability to bond properly

Following the first cleansing, the next action involves polishing the automobile to eliminate any type of flaws, such as swirl marks or scratches. Polishing makes certain a smooth surface, which is important for the layer to adhere appropriately and provide an uniform surface. After brightening, a surface area preparation spray is used to get rid of any type of staying deposits and make certain that the surface is totally tidy.

Safety Benefits

Frequently hailed for its exceptional protective qualities, a ceramic finish uses various advantages that significantly enhance lorry sturdiness. At its core, ceramic covering creates a hard, semi-permanent barrier over a lorry's outside, which functions as a guard against numerous environmental hazards. This sophisticated layer of defense effectively defends against UV rays, oxidation, and fading, keeping the vehicle's initial paint and luster. It lessens the dangers posed by unsafe pollutants such as bird droppings, tree sap, and roadway grime, which, if left unattended, can cause permanent damage.

Furthermore, ceramic layers exhibit hydrophobic homes, suggesting they repel water and help with a self-cleaning impact. This quality lowers the adherence of dust and mud, streamlining upkeep and cleansing processes. The covering's resistance to chemical etching even more makes sure that the automobile's surface area continues to be unblemished despite direct exposure to extreme cleaner and toxins.

Along with these safety benefits, the ceramic finish boosts an automobile's visual charm by producing a glossy coating that accentuates color deepness and quality. This not just sustains the car's visual charm but also contributes to its long-term worth by protecting the stability of its exterior over time.

Comparing to Conventional Techniques

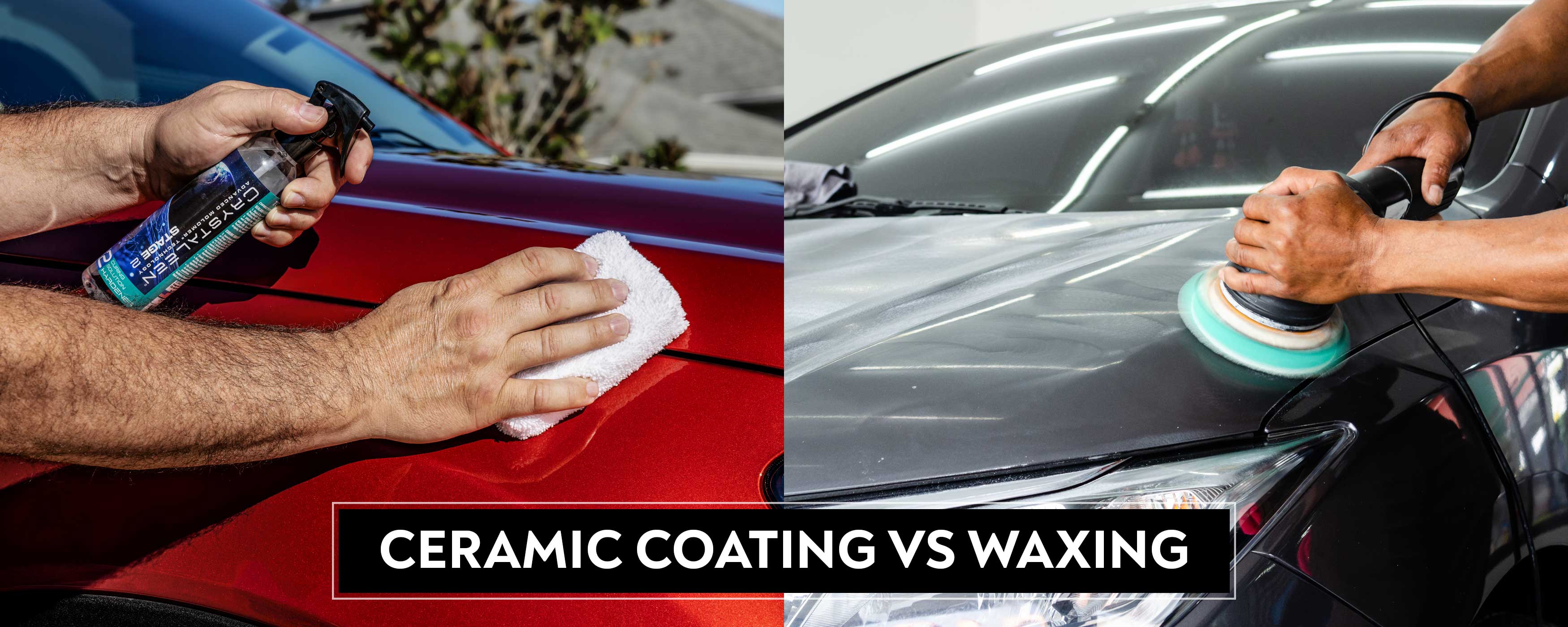

Unlike standard techniques of car protection, such as waxing or sealers, ceramic layers offer a more resilient and resilient service. Where waxes and official site sealers usually offer a short-term layer of protection, usually needing reapplication every few months, ceramic layers create a semi-permanent bond with the lorry's paint. This bond produces a protective layer that is immune to environmental impurities, UV damage, and minor abrasions.

Typical waxes are mostly composed of all-natural components like carnauba wax, providing a glossy coating yet lacking the durable protective high qualities of ceramic finishings. Sealers, while artificial and offering a little better resilience than waxes, still drop short in comparison to the durability and chemical resistance of ceramic finishings. The innovative innovation of ceramic layers integrates nanotechnology, which permits them to fill up in tiny flaws in the paint surface area, resulting in a smoother and extra hydrophobic finish.

In terms of application, ceramic layers call for a more thorough process, typically demanding professional setup to guarantee optimum efficiency. This contrasts with the relatively simple application of sealants and waxes, which can be applied in the house. Nonetheless, the exceptional security and visual enhancement offered by ceramic finishes justify the investment for those looking for long-term vehicle preservation.

Longevity and Maintenance

Exactly how does the durability of ceramic finishes equate right into ease of maintenance for vehicle owners? The advanced formulation of ceramic coverings provides a durable safety layer on the lorry's surface, which considerably prolongs the lifespan of the cars and truck's outside surface. This toughness indicates that the finish functions as a guard versus ecological pollutants such as UV rays, bird droppings, and road grime, which can otherwise degrade paintwork over time. Consequently, vehicles covered with ceramic items need less constant cleaning and describing initiatives, consequently decreasing maintenance time and prices for proprietors.

Moreover, the hydrophobic nature of ceramic company website finishings makes it possible for water and various other liquids to bead up and roll off the surface, bring dirt and debris with them. While the layer itself is long-lasting, it is not completely maintenance-free. Hence, ceramic coatings offer a useful equilibrium in between lasting durability and simplified upkeep for lorry treatment.

Verdict

Ceramic coverings, with their advanced chemical structure of silicon dioxide and titanium dioxide, provide a powerful barrier against ecological damages, dramatically boosting automobile sturdiness. The hydrophobic properties advertise self-cleaning, lowering upkeep efforts and protecting aesthetic appeal. When contrasted to standard techniques, ceramic coverings offer exceptional protection versus UV rays, oxidation, and chemical etching. This innovation expands the life expectancy of car exteriors, making it an use this link ingenious option for lasting conservation and minimal maintenance.

The solution of ceramic finishes is a meticulous procedure where the concentration of SiO2 can dramatically influence the covering's efficiency.Applying a ceramic finishing to a vehicle includes numerous vital steps, each necessary to guaranteeing ideal attachment and performance of the protective layer.Usually hailed for its extraordinary safety qualities, a ceramic finish offers various advantages that dramatically enhance automobile toughness. The advanced formulation of ceramic layers offers a robust safety layer on the automobile's surface, which considerably prolongs the life-span of the car's exterior finish.Ceramic finishings, with their advanced chemical structure of silicon dioxide and titanium dioxide, offer a powerful obstacle versus ecological damages, dramatically improving lorry durability.

Report this page